Precision Cost Reduction: Apparel Industry Enterprise Case Study

Precision Cost Reduction Case Study

An apparel fashion brand faced increasing cost pressures in recent years. Although their sales revenue grew, profit margins continued to decline, and operating costs kept rising. The main issues were found in raw material procurement, production processes, and inventory management. By collaborating with us, the company aimed to optimize their cost structure, improve financial efficiency, and drive profit growth.

Due to space constraints, only a few major issues are highlighted in this case study.

Step 1: Identifying the Issues

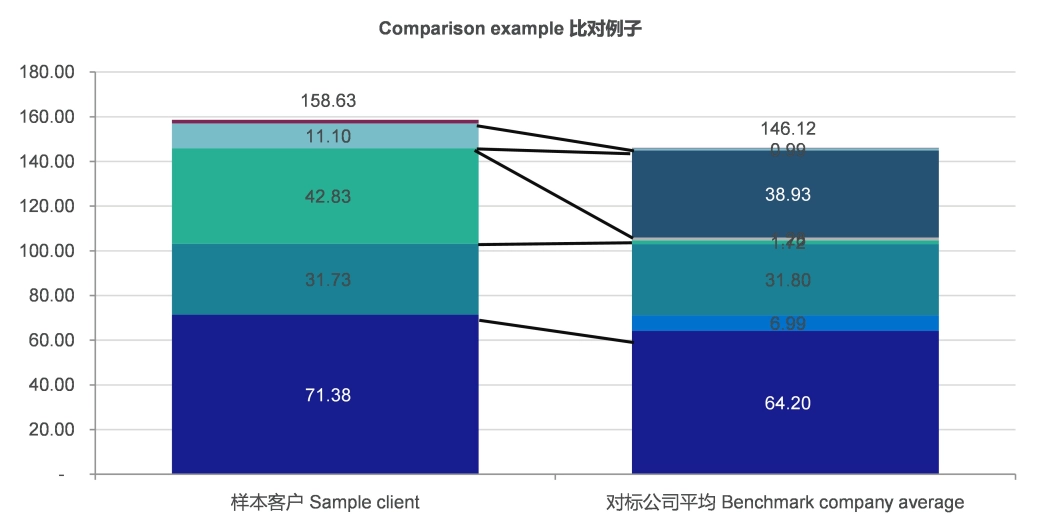

Through benchmarking against industry peers, this case reveals that the Sample client’s gross profit margin is only 39.7%, significantly lower than the average gross profit margin of 47.7% for the six benchmark companies, a difference of nearly 10%. This gap directly results in the client’s net profit margin being just 2.3%, compared to an average net profit margin of 11% for the benchmark companies. Further analysis identifies the following key issues with the client’s cost and inventory management:

- High raw material procurement costs: The client has limited supplier options and lacks effective procurement strategies and long-term agreements, which leads to significant price fluctuations and makes it difficult to ensure stable cost control.

- Excessive production waste: This is primarily due to unstandardized work processes and inconsistent operations, which reduce production efficiency and result in additional material waste.

- Poor inventory management: The client’s inventory management system fails to accurately predict market demand, leading to a large amount of unsold surplus products. The root cause of this issue is the inability to link real-time sales and inventory data from stores and distributors, which prevents production plans from aligning with actual market demand. As a result, production plans are based on inaccurate forecasts, leading to inefficiencies in both inventory management and production.

Step 2: Identifying Core Issues and Building a Cost Reduction Map

In the process of cost reduction and efficiency improvement, the key to success lies in accurately identifying the core issues and systematically outlining a clear "cost reduction map." Based on the issues identified in the Samply client's case, we proceed with the following steps:

1. Identify Cost and Efficiency Bottlenecks:

- Raw Material Procurement Costs: Due to a limited supplier base and the lack of long-term procurement agreements, there is significant price volatility. We assess the potential for supplier diversification, renegotiate more competitive pricing terms, and introduce long-term contracts to stabilize procurement costs.

- Excessive Production Waste: The lack of standardized processes and inconsistency in workflows have led to low efficiency and additional material waste. We conduct a thorough review of production processes to identify opportunities for optimization and standardization, reducing waste and improving production efficiency.

- Poor Inventory Management: The inability to accurately predict market demand and the failure to link real-time store and distributor sales data with production plans have resulted in excess inventory. This issue requires IT investment to strengthen the inventory management system, ensuring that real-time sales and inventory data accurately reflect market demand, allowing production plans to be adjusted accordingly.

2. Systematically Map Cost Reduction Opportunities Across the Value Chain:

- Procurement: Renegotiate supplier contracts, expand procurement channels, and optimize demand forecasting to reduce procurement cost fluctuations.

- Production: Standardize workflows, implement lean manufacturing practices, reduce waste, and enhance production efficiency.

- Inventory Management: Implement a real-time data-driven inventory management system that integrates sales and inventory data, ensuring production plans align with market demand, thereby reducing excess inventory and associated holding costs.

3. Prioritize Cost Reduction Actions: Based on the impact and feasibility of each area, we prioritize the cost reduction opportunities that would have the most significant financial impact. This ensures efficient resource allocation and focuses efforts on the highest-priority issues.

4. Visualize the Cost Reduction Map: All identified cost reduction opportunities and optimization paths has been systematically organized into a visual "cost reduction map," providing clear guidance for the formulation and execution of future plans. This map serves as the navigational tool for executing the cost reduction strategy, ensuring that every step aligns with the company’s financial objectives.

By systematically identifying and addressing these core issues, we can create a targeted cost reduction plan that helps clients achieve significant improvements in profitability and operational efficiency.

Step 3 & 4: Implementing and Sustaining Cost Reduction Measures with Continuous Monitoring

In the final stages of our cost reduction strategy, we work closely with the Sample client to develop a set of Key Performance Indicators (KPIs) that are aligned with the company’s financial and operational objectives. These KPIs serve as measurable targets for tracking the success of the implemented cost reduction initiatives. The main cost of sales and inventory related KPIs focus on reducing discount dependency, optimizing the membership system, bundled sales, optimizing supply chain cost reduction, improving production efficiency, and increasing inventory turnover rate, among others.

Once the KPIs are established, we begin executing the action plans, providing the necessary support and resources for each initiative. Our team works alongside the Sample client to ensure that the initiatives are implemented effectively, on time, and within the budget.

Continuous Monitoring and Adjustment: We believe that sustainability is key to a successful cost reduction program. Therefore, we set up a robust monitoring system to track progress against KPIs, ensuring that any deviations from the expected outcomes are promptly addressed. Regular reviews are conducted to evaluate performance and adjust strategies where necessary. These reviews gradually transited to be led by the management team, allowing them to take ownership of the cost reduction efforts.

Empowering Management: As part of the transition process, we empower the management team by equipping them with the tools, frameworks, and insights needed to continue managing cost reduction independently. Our ongoing involvement will then be limited to periodic industry updates and sharing market intelligence to keep them informed about new trends, competitive pressures, and potential opportunities for further optimization.

By giving the management team the responsibility and authority to handle the day-to-day management of the cost reduction process, we ensure that the improvements are sustainable over the long term. Our role then shift to periodic check-ins, where we share best practices, industry insights, and provide guidance where necessary. This transition not only strengthens the internal capabilities of the client’s management team but also ensures that cost reduction becomes a continuous improvement process integrated into the company’s culture.

Conclusion

Through the collaborative development of KPIs, effective implementation of cost reduction initiatives, and the transition of ownership to the management team, we have built a sustainable framework that enables ongoing operational efficiency improvements. Our approach not only delivered immediate savings but also strengthened the internal capabilities of the Sample client to drive continuous value creation. Moving forward, our role evolves into a strategic partner, providing industry insights and best practice sharing to support the client's long-term success.